Supply chain control tower – beyond visibility, driving value

Reading Time: 4 minutes

As supply chains continue to become more complex and global, businesses are facing an increasing need to gain greater visibility and control over their operations. CPG companies across the globe are tasked with managing complex supply chain networks to navigate operational risks and regulatory challenges. A modern supply chain control tower (SCT) leveraging AI empowers businesses to manage their supply chains proactively. With end-to-end visibility across the entire network of suppliers, manufacturers, and business partners, SCT’s have delivered tangible value such as reduce logistics costs by upto 5%, reduce inventory costs by upto 15%. Ranging from extreme weather conditions to truck accidents in real time, SCTs also enable businesses with supply chain analytics to take corrective measures in real time without disrupting the flow to ensure agile and resilient operations.

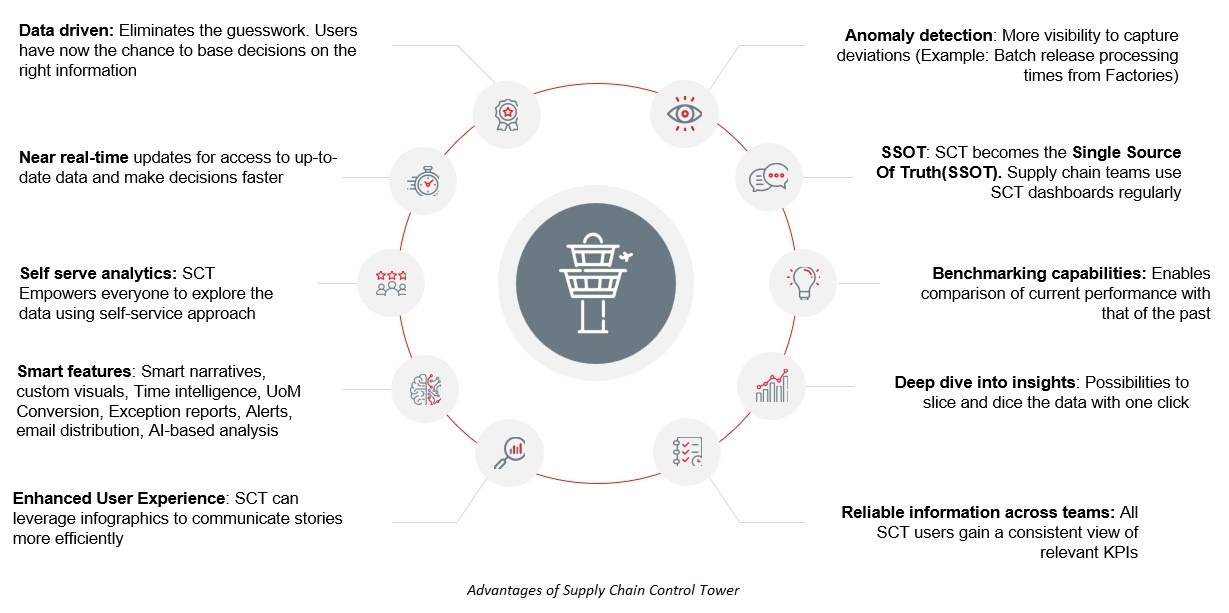

Key features of a SCT

– Near real time visibility: Control towers can provide a 360 degree view of the entire supply chain network with the latest insights from data. Leaders can monitor the network including suppliers, manufacturers, transporters warehouses, third party logistics under one roof and manage their supply chain to increase efficiency and reduce risks. This level of visibility can help organizations identify potential bottlenecks, anticipate supply chain disruptions, and proactively mitigate risks before they become major issues.

– Better decision making: A data-driven control tower helps organizations optimize their supply chain operations by identifying areas of optimization. Predictive analytics can help supply chain managers make informed decisions and optimize operations by anticipating disruptions, identifying bottlenecks and improving inventory management, capacity planning, routing and overall efficiency of the supply chain.

– Proactive supplier collaboration: SCT allows seamless collaboration between partners, suppliers, and logistics providers to promote cross organizational collaboration for faster issue resolution, lower costs, and higher customer satisfaction. By providing a single source of truth for supply chain data, it facilitates better communication and collaboration, reducing the time and effort required to resolve issues.

– Business agility –Enterprises can stay agile and be responsive to changing market conditions. With the ability to quickly adapt to disruptions in the supply chain, organizations can maintain business continuity and ensure customer satisfaction even in challenging times.

Key considerations while establishing a SCT

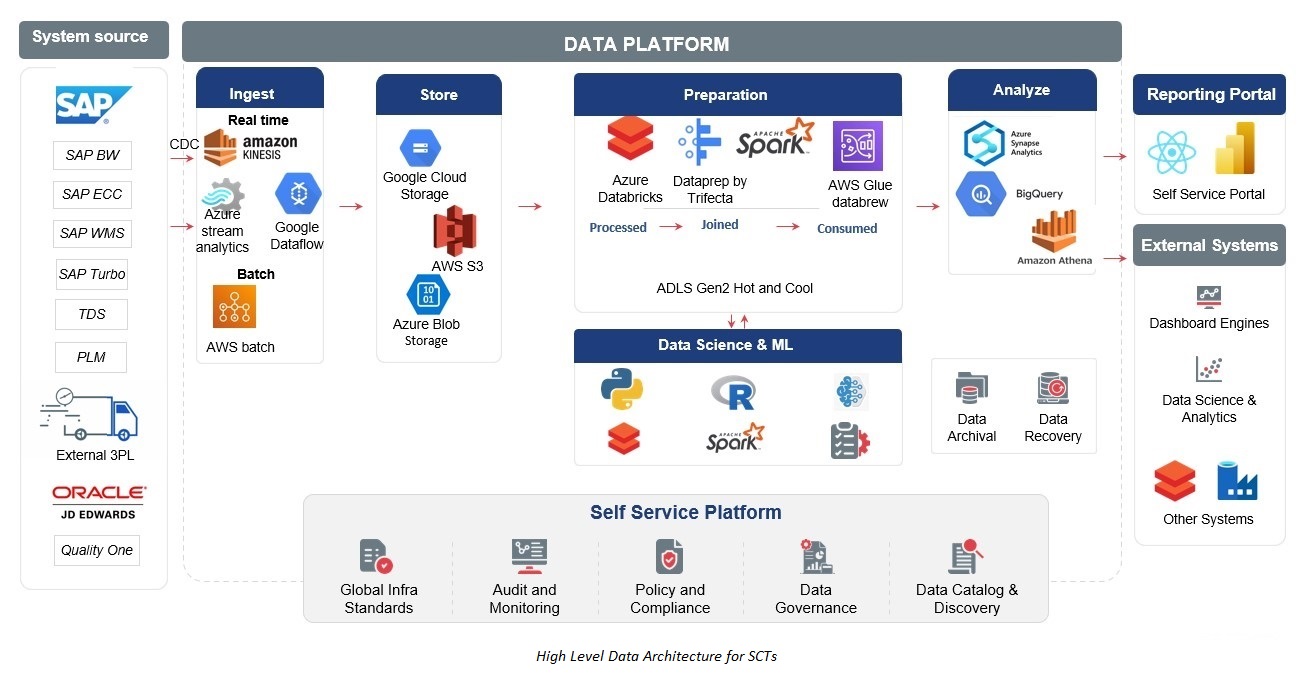

1. Data integration:

Supply chains generate enormous quantities of data from a variety of sources, including ERP systems, transportation management systems, warehouse management systems, and IoT devices. To provide a comprehensive view of the supply chain, it is necessary to integrate all of this disparate data into a single platform through fast and automated data pipelines. Custom built data connectors built using a LCNC architecture helps in streamlining the integration of disperse data sources and allows for quick integration of newer data sources.

2. Data governance and data cataloging:

Data governance is necessary to ensure that the data utilized in the supply chain control tower is accurate, pertinent, and compliant with regulatory requirements. It also ensures the SCT is driven by high quality data that is accurate and comprehensive.

Data cataloging makes use of metadata to provide organizations with a single, overarching view along with deeper visibility into their data assets. This allows data users and analysts to locate data for specific supply chain use cases.

3. Advanced analytics capabilities:

Modern control towers need to increasingly leverage Machine Learning (ML), to conduct what-if analysis, run simulations of supply and demand changes and provide prescriptive guidance for how to address problems. Timely delivery of actionable intelligence is critical to improve inventory turnover, reduce stock outs, material shortages.

4. Data standardization:

It is important to establish clear data standards and validation processes, as well as using reliable data sources. Diverse systems and data sources utilize various data formats and standards, which can lead to issues in data quality. Standardizing the format and structure of data, regular data audits and quality checks. Should be conducted to identify and correct any errors or inconsistencies.

Logical data structure for SCT

SCTs require data from both structured and unstructured sources such as ERP, barcodes, remote sensors, 3PL systems, CRM and more to provide real-time insights. With interconnected modules that cover critical elements of the supply chain from plan to source to deliver, SCT can work on key process hotspots and identify opportunities for a holistic supply chain BI. By applying advanced analytics to the data gathered, the SCT can provide up to date information with user friendly reports and dashboards for visibility into core functions such as order management, inventory levels, manufacturing and more. Businesses can design custom built dashboards to visualize specific insights and KPIs for granular visibility into each operation to improve agility and respond to operational glitches.

Conclusion

With features like automated decision making and self correction, SCT helps companies to identify and trace issues to avoid them in the future. To drive consistent outcomes with a SCT, businesses need to have a robust data foundation to leverage comprehensive, accurate and latest data, which can result in effective decision-making, operational excellence and reduced cost overheads.

Featured blogs

Subscribe to get latest insights

Talk to our experts

Get the best ROI with Sigmoid’s services in data engineering and AI

Featured blogs

Talk to our experts

Get the best ROI with Sigmoid’s services in data engineering and AI