CPG R&D: The next big opportunity for AI-led digital transformation

Reading Time: 7 minutes

Consumer Goods and F&B enterprises are hitting a critical innovation bottleneck. Traditional R&D strategies are failing to keep pace with market dynamics—product portfolios are growing more complex, ingredient costs are climbing, and sustainability pressures are mounting. One thing is clear– incremental improvements are no longer enough. This situation demands reimagining R&D through AI-driven technological enablement. Organizations can transform complex challenges into strategic opportunities by combining advanced data analytics, for product development , artificial intelligence, and deep domain expertise. This is where technology becomes more than a tool—it’s a catalyst for breakthrough innovation.

R&D and the art of mastering complexity

Managing a complex set of interdependent, cross-functional tasks is a significant challenge. A prominent European CPG company, after analyzing the complexity of its product and packaging-related activities, discovered that a single product line could involve dozens of concurrent activities. It is not hard to see why, even for top-performing organizations, maintaining an optimal balance between delivered value and cost across the entire product and packaging portfolio is extraordinarily difficult.

Typically companies have been trying to address this challenge by optimizing alignment of R&D with partner functions, through enterprise processes like stage gate for innovation or structural integration of R&D in marketing and/or supply chain. Many global CPGs have introduced highly centralized innovation organizations with operational support located in markets.

However, it is becoming increasingly evident that organizational efficiency alone is insufficient for R&D to handle the complexity of balancing innovation, productivity, ESG, and QFS requirements while ensuring sustainable competitiveness of product portfolios. More specifically, innovation growth is progressively hard to realize with ingredient and packaging costs often already exceeding 60% of COGS in CPG or F&B companies.

This leaves little or no space for additional investment in, for example, more personalized offerings in Beauty care or alternative protein technology in Foods, to name just a few. Net zero ambitions and extended producer responsibility schemes are adding further complexity and cost to the equation: raw materials, ingredients and packaging are estimated to drive over 60% of emissions by some companies and the high cost and relatively limited availability of sustainable food packaging solutions are challenges for waste and EPR [Extended Producer Responsibility] fees reduction.

Why R&D needs a digital overhaul infused with AI

Sophisticated enterprise processes like stage-gate investment pipelines and project portfolio management were traditionally set up for innovation development, but today they must integrate Productivity, ESG and QFS requirements. These processes are heavily data-sensitive at many levels. In a typical CPG R&D organization, data is constantly exchanged across a large variety of interfaces both within the function as well as with other functions, markets, suppliers and 3rd parties like auditors or regulators.

A large CPG company found that R&D associates operated at any moment in time across at least 30 different major interfaces, enabling the development and delivery of many hundreds of projects.

With this high level of complexity required for competitiveness, R&D operations require effective data management and data science solutions to step-change their contribution to the business. With the advent of AI technology, there is the prospect of associates to navigate complex challenges in using AI in product development– leveraging machine learning and automation to generate insights, optimize processes, and accelerate decision-making beyond the capacity of even the most optimized manual workflows.

Hence, the digital transformation in the CPG industry represents a critical opportunity for R&D to drive innovation at scale. Interestingly, while functions like marketing, supply chain, and finance have made significant strides in adopting digital technologies for automation and analytics, R&D teams still lag in leveraging these tools.

Recognizing this gap, CPG companies are increasingly prioritizing investment in R&D digital transformation as a critical step to unlock the full potential of value creation across all initiatives. This also complements enterprise-wide initiatives such as digital transformation in retail and CPG procurement digital transformation, aligning all functions under a unified strategy.

Digital transformation of R&D activities can reduce engineering hours by as much as 20%, cut rework by as much as 50%, and enable cost reductions of 5% to 30%1.

– [Source: Bain]

Key steps to effective digital and AI enablement of R&D

There are many components to building effective digital strategies in R&D, but the following common steps can become a good starting point for ensuring digital readiness:

- Ensure R&D AI roadmaps link to enterprise value creation

- Prioritize R&D sub-processes with measurable impact on the value creation process

- Engage R&D Experts early to ensure that data products deliver

Successful teams start with Enterprise Value Creation goals in mind when designing R&D AI roadmaps. Too often we see R&D teams and their digital partners ignore this critical requirement and focus on R&D productivity tools instead. As a consequence, R&D digital pipelines can feel disconnected from the business reality and fail to get prioritized in already over-called data, analytics and AI investment budgets. Value creation goals can be linked to any of the levers impacted by R&D: innovation, productivity, ESG and quality & food safety.

For example, an R&D client is seeking to substantially improve the NPS impact of global brand launches by reducing the time to first launch for each target market while still meeting critical performance, regulatory and cost parameters in each market. Another global CPG client is seeking to optimize the balance between investments in sustainable food packaging solutions and eco-modulated fees under extended producer responsibility schemes.

Using the innovation process as an example, R&D impact is typically measured by product launch readiness to project brief, competitive product performance in the market and the generation of distinctive, competitive claims. Similar measurement approaches apply across productivity, ESG and QFS. What these outcomes have in common, is that they depend on many, highly complex, interdependent tasks and data sets. Selecting the right data and analytics targets from R&D sub-processes is not as straightforward and takes time.

In our work on packaging portfolio value optimization and extended producer responsibility, a thorough assessment highlighted that a phased digital pipeline build starting with essential reporting and analysis capability across different functions is the right starting point for the organization. The digital pipeline explicitly incorporates predictive analytics in CPG and AI pilots as technology matures and organizational data readiness evolves. The expectation is that these products will enable increasingly sophisticated product scenario planning, supplier selection and insights for innovative packaging solutions, opening up new avenues for value creation.

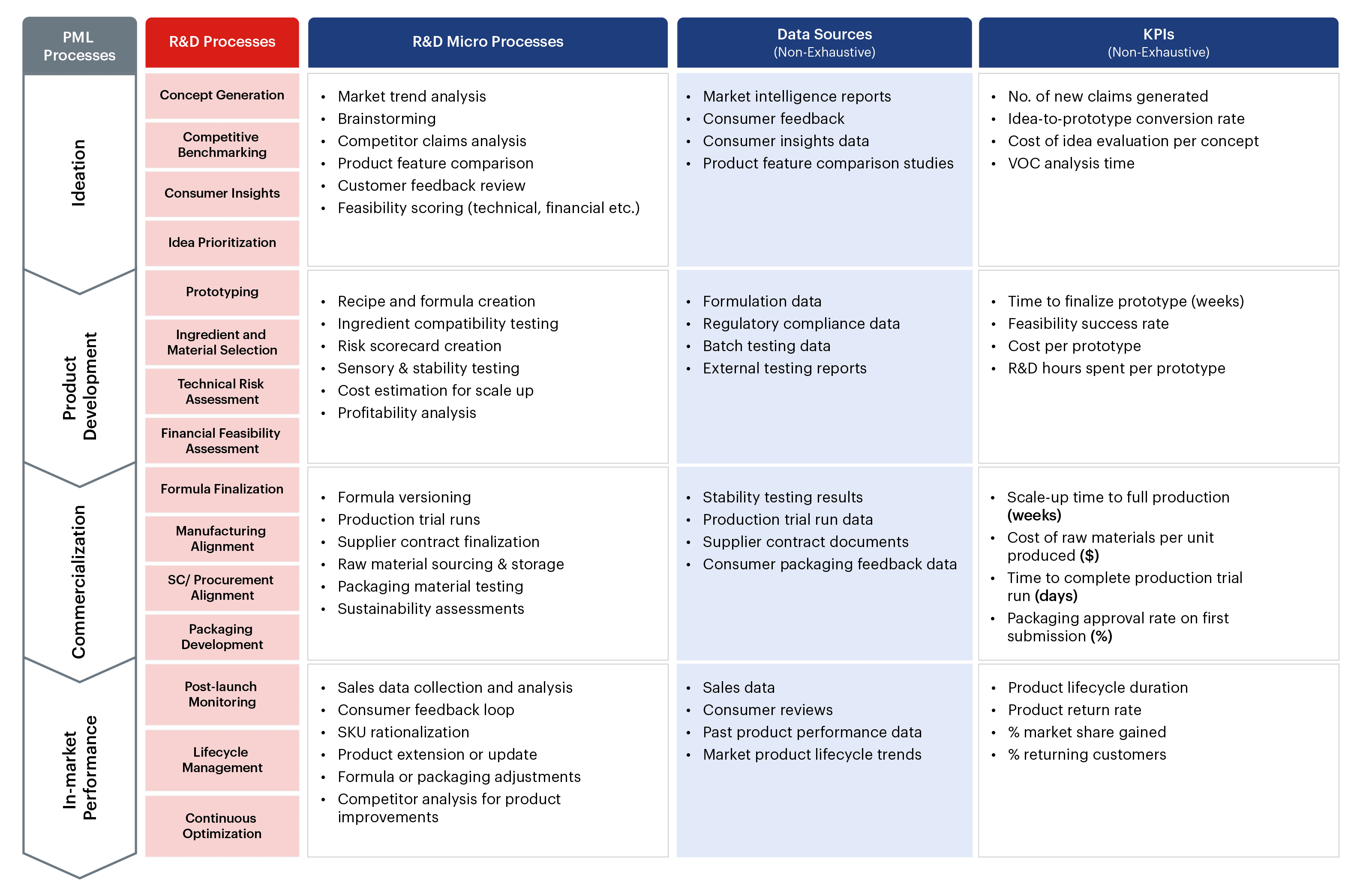

Fig.1.– Example of R&D sub-processes complexity

Too often, digital and R&D teams fail to collaborate effectively in defining which data products to develop or purchase. This functionally siloed approach not only results in wasted resources but also undermines R&D teams’ confidence in digital enablement, and “tool fatigue” amongst associates. A more effective approach is to co-create value-driven data and AI solutions using the steps as described above. This is specifically true for the identification of the relevant R&D sub-process and data targets for using AI in product development. The roles of R&D and Digital experts are interdependent in this process: R&D domain expertise drives ideas for technology solutions, similarly, new technology development, specifically in AI, can stimulate ideas for new value creation opportunities in R&D.

Typically, we observe that for more immediate, scalable impact, products that help improve data access, transparency and interpretation help R&D associates build confidence in using and improving their extensive portfolio of data sources. This approach also helps R&D identify selected subprocesses for piloting technologies with potential step-change impact on value creation. Emerging examples include use of AI to boost the creative process by improving insight generation and validation, replication of real-world consumer product experience and process workflows based on manufacturing digital twin technology.

Digital transformation in R&D is not about implementing technology, but about creating collaborative ecosystems where R&D domain expertise and digital innovation intersect. The most powerful solutions emerge when we break down functional silos and co-create value-driven technologies that amplify human insight and creativity.

Conclusion

As organizations navigate increasingly complex portfolios, sustainability demands, and data-intensive processes, the traditional approaches to R&D are proving insufficient. Success requires a fundamental shift: aligning digital capabilities with enterprise value creation, focusing on high-impact processes, and fostering genuine collaboration between R&D and digital teams.

With deep expertise in analytics, AI, and CPG domain knowledge, Sigmoid helps leading enterprises execute transformative R&D strategies. By integrating data analytics for product development, predictive modeling, and advanced technologies, we partner with leading CPG companies to co-create transformative solutions that can elevate R&D operations from being cost centres to strategic innovation engines—driving efficiency, sustainability, and market leadership in a complex global marketplace.

Our approach ensures that R&D transformation complements enterprise-wide initiatives like digital transformation in retail and CPG procurement digital transformation, creating a cohesive foundation for scalable innovation and market leadership.

About the author

Michel Oostwal, PhD, is the Founder and CEO of Orange Transformation Group (OTG), an executive consultancy focusing on enhancing R&D effectiveness in global CPG companies, particularly through AI. He is also a senior advisor to Sigmoid and other global CPG organisations. Before founding OTG, Michel held SVP/CRDO roles at Mars in North America and the Asia-Pacific region.

Featured blogs

Subscribe to get latest insights

Talk to our experts

Get the best ROI with Sigmoid’s services in data engineering and AI

Featured blogs

Talk to our experts

Get the best ROI with Sigmoid’s services in data engineering and AI